Optimizing Low Voltage Panel Boards with PET Expandable Braided Sleeving

In real-world electrical work, messy or unprotected cables can cause big problems. Especially in low voltage panels, which show up everywhere from homes to industrial control rooms. PET braided sleeving is a simple, budget-friendly fix that keeps wires neat, safe, and out of trouble.

Where does Braided Sleeving Actually Go in a Low Voltage Panel?

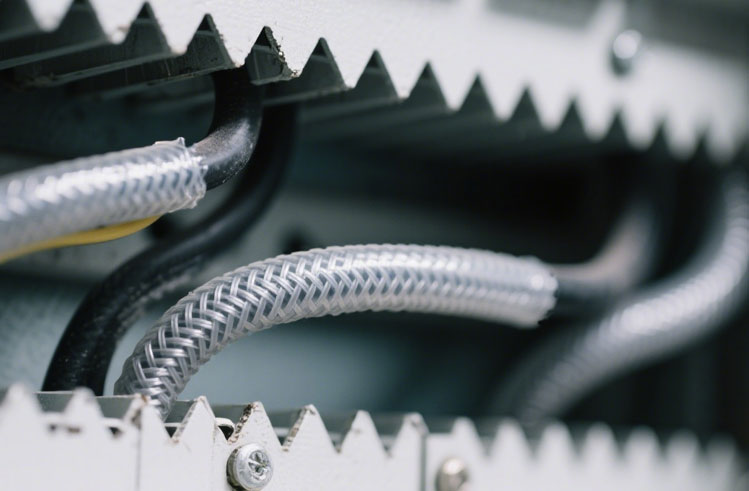

Inside these panels, you’ll find tons of wires running between breakers, contactors, relays, and other parts. It’s a pretty tight space, and with so many cables packed in, there’s always a risk of rubbing, bending, or even interference. That’s where braided sleeving helps keep everything protected and in place.

Here’s how PET braided sleeving really comes in handy:

You can use it to bundle up a bunch of wires so they’re easier to route and less messy. It adds a layer of protection when cables are running over sharp edges or tight bends. It also helps prevent the insulation from wearing out if wires rub during transport or movement. And with different colors or expandable designs, it’s easier to spot and manage different cables.

Key Benefits for Electrical Panel Builders

Panel builders and component distributors—particularly in regions like Europe, where standards are stringent—choose PET braided sleeving for several reasons:

✅ Abrasion Resistance

Cables inside panels are subject to vibration and constant interaction with other components. PET braided sleeving forms a flexible barrier that prevents cuts, scrapes, and wear on insulation jackets.

✅ Expandable Structure

The expandable weave design allows a single sleeve size to accommodate a wide range of cable diameters. This flexibility is critical in panel manufacturing, where customization is frequent.

✅ Organized Cable Management

Professionally organized wiring not only looks better but improves serviceability and reduces error during maintenance. Sleeving helps bundle and separate functional groups within the enclosure.

✅ Compliance with Industry Standards

High-quality PET braided sleeves meet compliance needs such as:

- RoHS / REACH (for environmental safety)

- UL94 V-2 or V-0 flame retardancy (for fire safety, if required)

- Halogen-free or low smoke variants, important for enclosed or densely populated installations.

Without REACH, RoHS, and flame retardancy test reports, products cannot be accepted in many markets, especially within the EU.

As the industry shifts toward more efficient and reliable panel solutions, PET expandable braided sleeving is no longer just an add-on—it’s a smart, future-ready choice. It helps you deliver safer, neater systems and stay compliant with evolving standards.it’s what forward-thinking manufacturers and distributors are turning to.