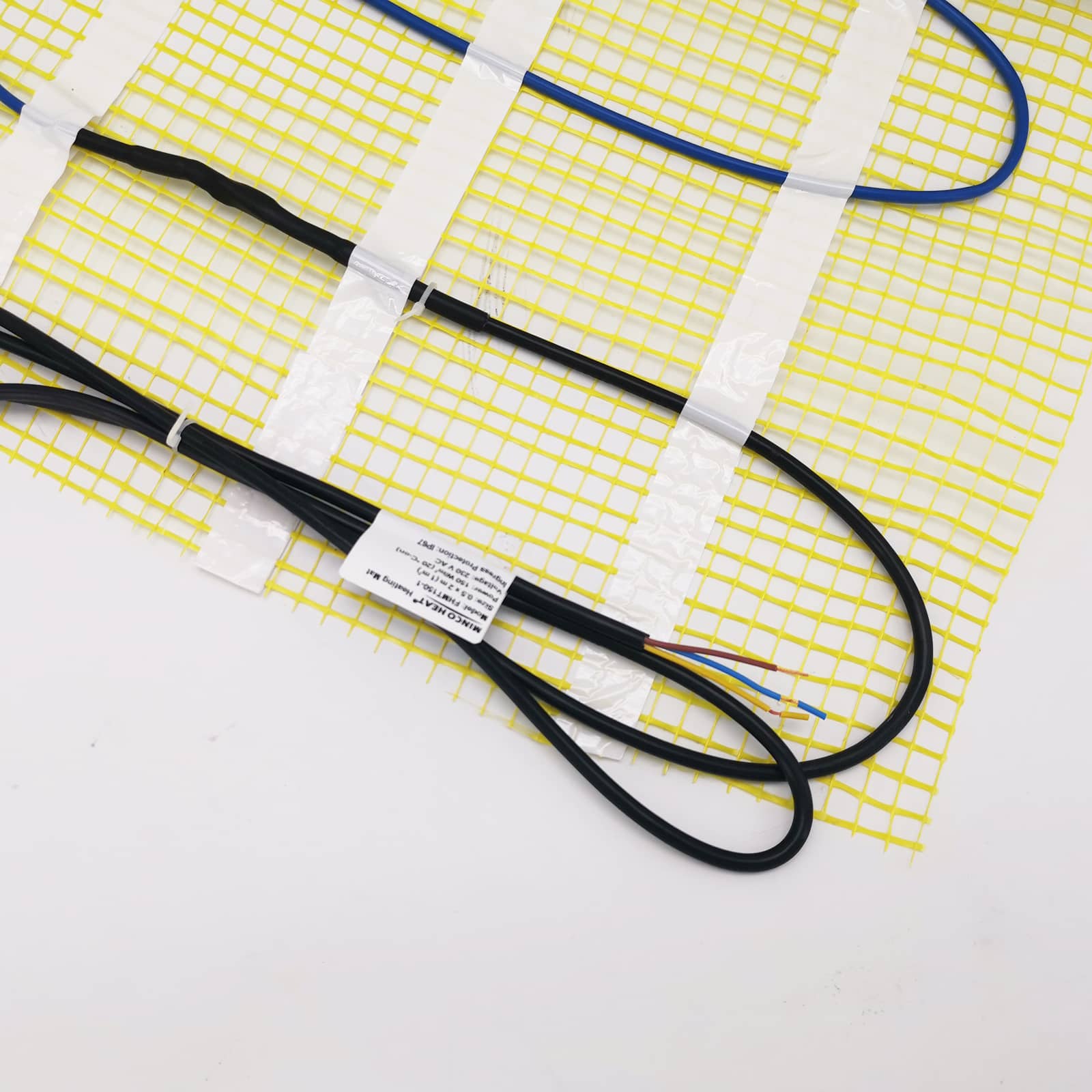

Does High-Density Cable Sleeving Prevent Liquid Damage?

Cables in industrial environments rarely exist in isolation—they are often integrated into complex machinery, production lines, or vehicle systems. Even when a cable appears robust on the outside, exposure to liquids and chemicals can silently degrade its performance over time.

This is where high-density cable sleeving plays a critical role. Unlike standard braided sleeving, high-density designs significantly reduce gaps in the braid structure, creating a stronger physical barrier against liquid intrusion.

Why Density Matters in Cable Sleeving

When selecting high-density cable sleeving, density is not a vague concept—it is defined by specific technical parameters that directly affect protection performance:

Parameter

Description

Impact on Corrosion & Liquid Resistance

Monofilament Diameter

The thickness of each individual strand in the braid

Thicker monofilaments provide stronger physical barriers and can withstand more aggressive spray and liquid exposure.

Carriers

The number of spools on the braiding machine

A higher carrier count (e.g. 24, 32, or 48 carriers) creates smaller, tighter mesh openings, significantly reducing liquid penetration.

Braid Angle

The angle at which the strands intersect

A more vertical braid angle improves longitudinal coverage, while a more angled braid can introduce gaps that allow liquid ingress.

When Standard Sleeving Is Not Enough

Even premium materials can fail if the braid density is insufficient. In environments such as food processing plants, chemical facilities, automotive engine compartments, or hydraulic systems, corrosive liquids often find their way through structural gaps.

To further enhance protection, engineers commonly adopt two proven solutions:

Overlap Design

Wrap-around or overlap sleeving introduces an intentional overlap zone along the edges, providing an additional barrier that blocks liquid entry points more effectively than traditional tubular designs.

Double-Layer Braided Sleeving

Applying two layers of high-density cable sleeving ensures that any gaps in the first layer are covered by the second. This method is widely used in aerospace and industrial applications for both chemical resistance and long-term durability.

Long-Term Reliability Through Smart Sleeving Selection

By focusing on braid density, structural parameters, and reinforcement methods, high-density cable sleeving delivers reliable protection against liquid exposure, chemical corrosion, and environmental wear. Proper selection during the design and specification stage ensures extended cable life and improved system reliability in demanding industrial conditions.