Heating mats (also known as heating pads or electric heating mats) are categorized into different types based on "protection rating, heating power, and material." They must be matched to the core needs of various environments such as households, industries, and agriculture, while installation should avoid environment-specific risks (e.g., moisture, high temperatures, and heavy object compression).

Classification of Core Environment and Selection of Heating Seat

The "risk points" and "heating requirements" vary greatly in different environments, so when choosing, priority should be given to locking in "protective performance" and "power parameters" before matching materials.

1. Family environment: Focus on "safety against electric shock+low noise"

Family scenes are mainly used for bedroom (mattress heating), living room (carpet heating), and bathroom (floor insulation), with core requirements of safety, comfort, and non-interference.

Key points for selection:

- Protection level: It must reach IPX4 or above (splash proof), and the bathroom should choose IPX7 (short-term immersion) to avoid danger caused by splashing water during showering or water accumulation on the floor.

- Heating power: Choose 60-100W (single person) and 120-180W (double person) for the bedroom mattress heating seat to avoid excessive power causing dry and hot sleep; Choose 150-250W for the living room carpet heating mat to meet local heating needs.

- Material: The mattress heating mat should be made of cotton or suede surface (skin friendly and breathable), and the bathroom should be made of PVC waterproof surface (easy to clean), and it should have an "automatic temperature limit function" (automatically power off when the temperature exceeds 40 ℃).

Typical products:

- Household double waterproof electric mattress, bathroom anti slip heating floor mat.

2. Industrial environment: focus on "high temperature resistance+aging resistance"

In industrial scenarios, it is commonly used for equipment insulation (such as reaction vessels and tank outer walls), pipeline tracing (to prevent medium solidification), and local heating in workshops. The core requirements are resistance to harsh environments and long-term stable operation.

Key points for selection:

- Protection level: At least IPX5 (anti spray), IPX6 (anti strong spray) is required for outdoor or humid workshops to prevent industrial water and dust from entering.

- Heating power: For equipment insulation, choose 200-500W/㎡ (adjusted according to the solidification point of the medium, such as 300W/㎡ or more for asphalt storage tanks), and for pipeline heat tracing, choose 100-300W/m (matched according to the pipeline diameter).

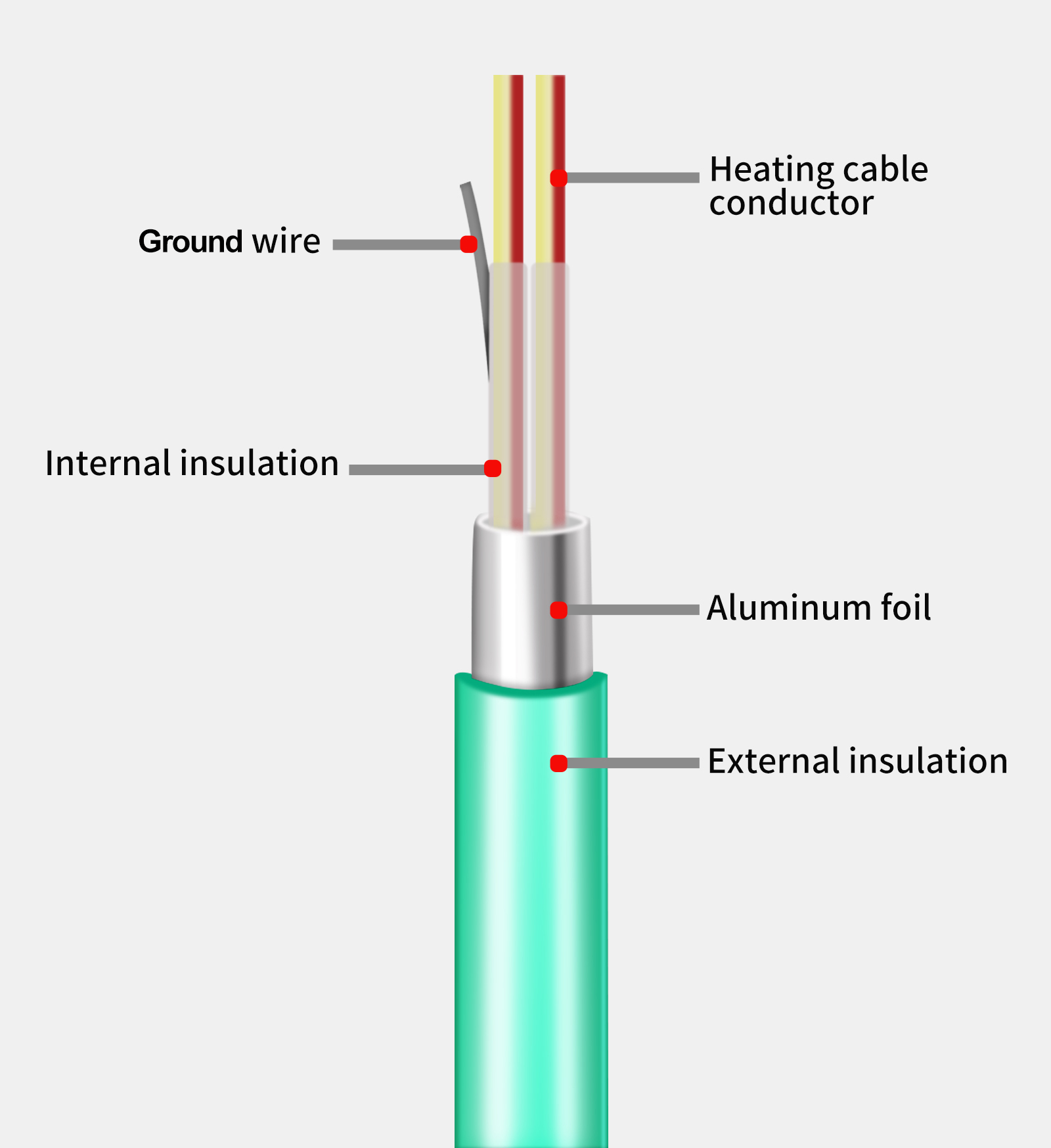

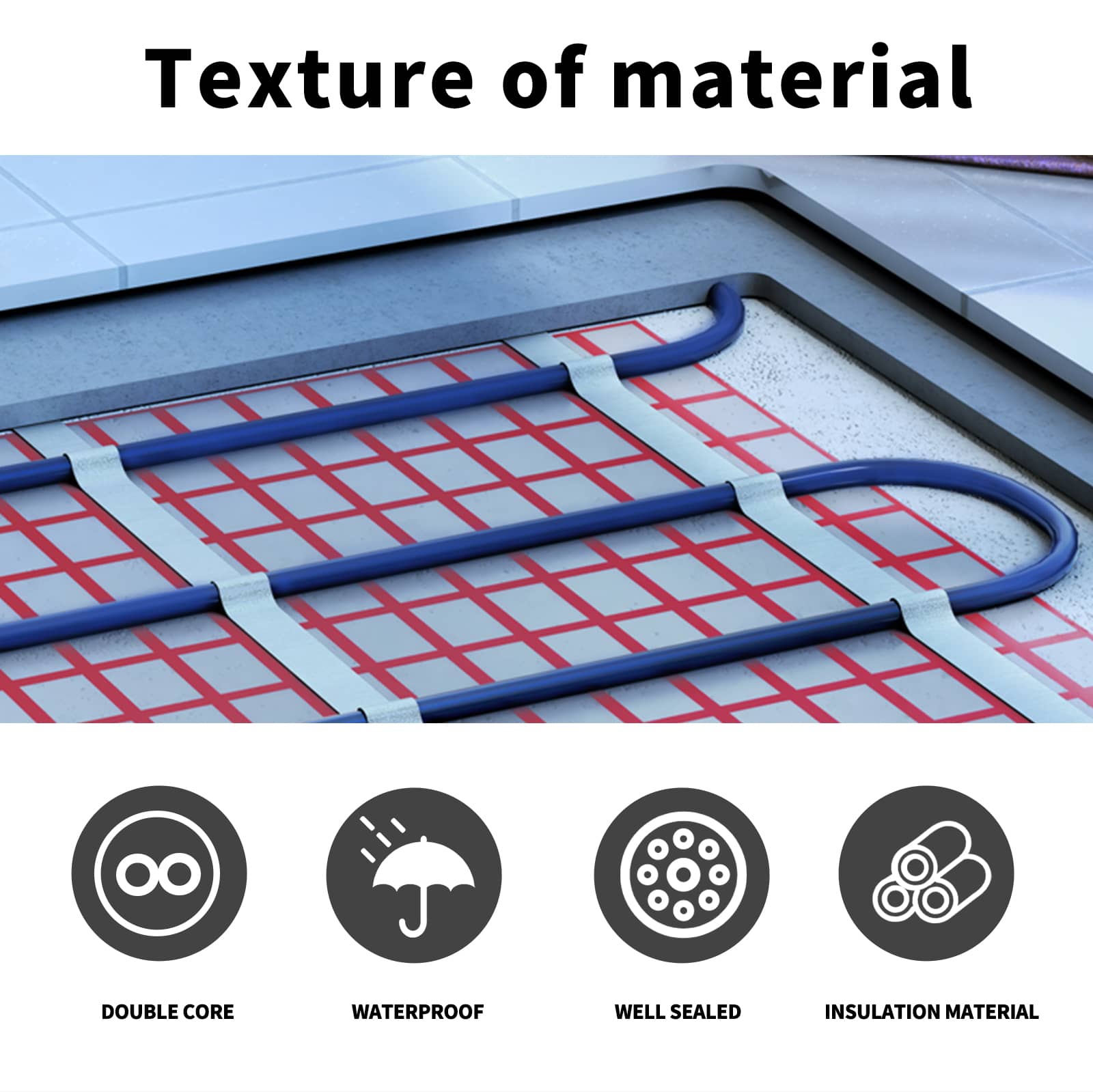

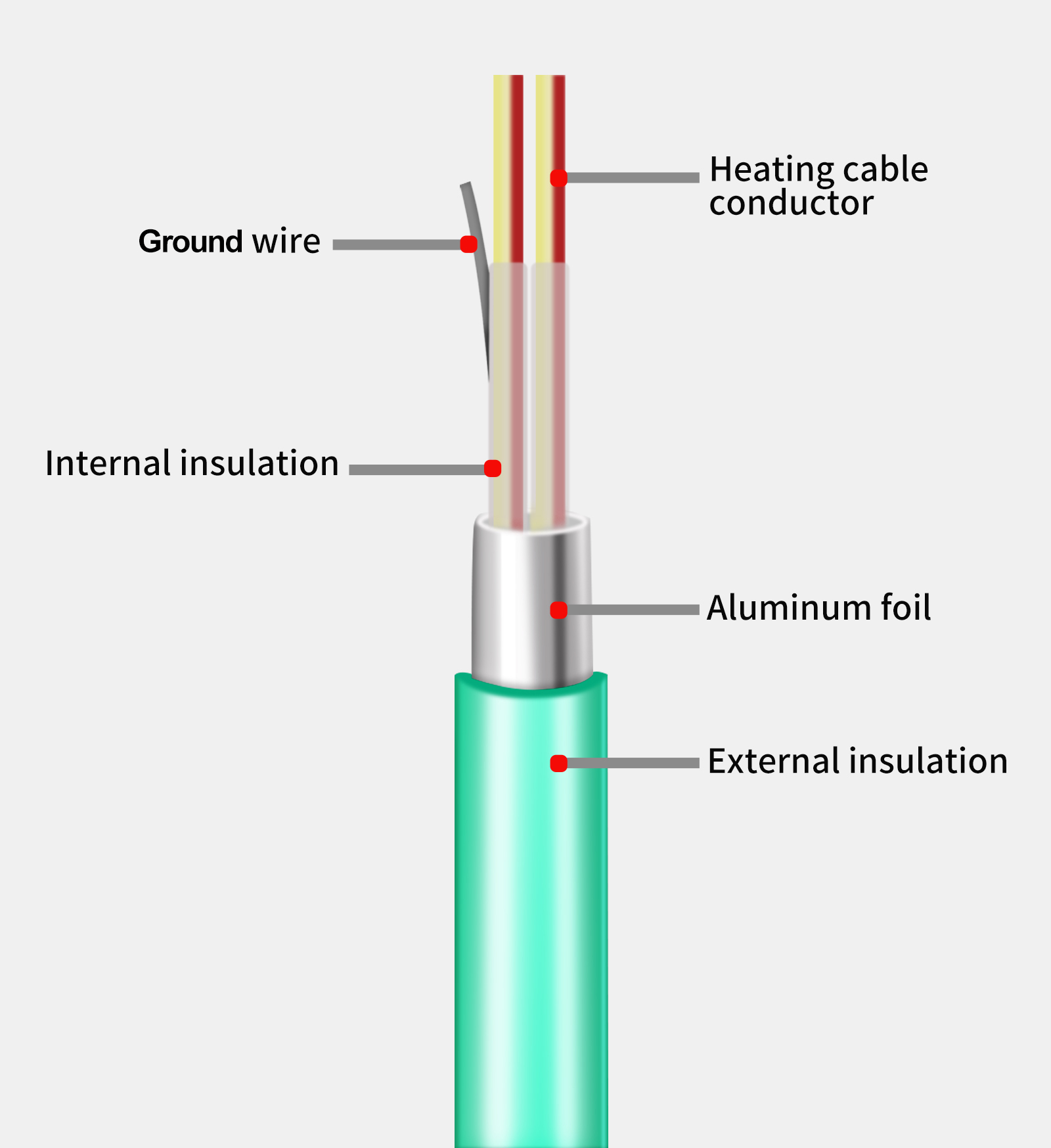

- Material: The surface layer is made of silicone rubber or fluoroplastic (temperature resistance -40 ℃~200 ℃, resistant to engine oil and chemical corrosion), and the internal heating wire is made of nickel chromium alloy (anti-oxidation, with a service life of more than 10 years).

Typical products:

- Industrial silicone rubber heating mat, pipeline heat tracing heating mat.

3. Agricultural environment: focus on "moisture-proof+uniform heating"

Agricultural scenarios are mainly used for greenhouse (soil heating), seedling box (seedling insulation), and animal husbandry (such as piglet insulation and chick rearing), with core requirements of moisture resistance, uniform heating, and no damage to animals and plants.

Key points for selection:

- Protection level: IPX4 (anti dew, irrigation splash), additional PE waterproof film wrapping is required for buried soil use (to prevent soil moisture infiltration).

- Heating power: Select 80-150W/㎡ for greenhouse soil heating (maintaining soil temperature of 15-25 ℃, suitable for vegetable and flower growth); Select 50-100W seedling box (precise temperature control in small space).

- Material: The surface layer is made of aging resistant PET material (resistant to ultraviolet radiation and soil corrosion), avoiding the use of easily degradable cotton materials. The spacing between heating wires should be uniform (with an error of ≤ 2cm) to prevent local high temperature from damaging the root system.

Typical products:

- greenhouse soil heating mat, seedling box dedicated heating mat.

4. Outdoor environment: focus on "cold resistance+wind and rain resistance"

Outdoor scenes are often used for camping tents (heating), outdoor equipment (such as monitoring boxes for insulation), and pedestrian walkways (snow melting assistance), with the core requirements being resistance to low temperatures and wind and rain erosion.

Key points for selection:

- Protection grade: IPX6 and above (to prevent rainstorm and strong wind from carrying rainwater), IPX8 (buried and ponding resistant) is required for outdoor snow melting.

- Heating power: Choose 100-200W for tent heating (fast heating in small spaces, used with tent insulation layer); Select 80-150W for outdoor equipment insulation (maintain the internal temperature of the equipment at 5-10 ℃ to prevent component freezing damage).

- Material: The surface layer is made of wear-resistant Oxford cloth and waterproof coating (scratch resistant and tear resistant), with an internal insulation cotton layer (to reduce heat loss). The heating wire needs to be equipped with "low temperature start protection" (can be powered on normally at -30 ℃ to avoid abnormal resistance at low temperatures).

Typical products:

- Outdoor camping electric heating mat, outdoor equipment insulation heating mat.

General installation specifications and environment specific precautions

The core of installation is to adapt to environmental risks. Based on the general steps, protective measures need to be added for different environments to avoid safety hazards or performance failures.

1. Universal installation steps (applicable to all environments):

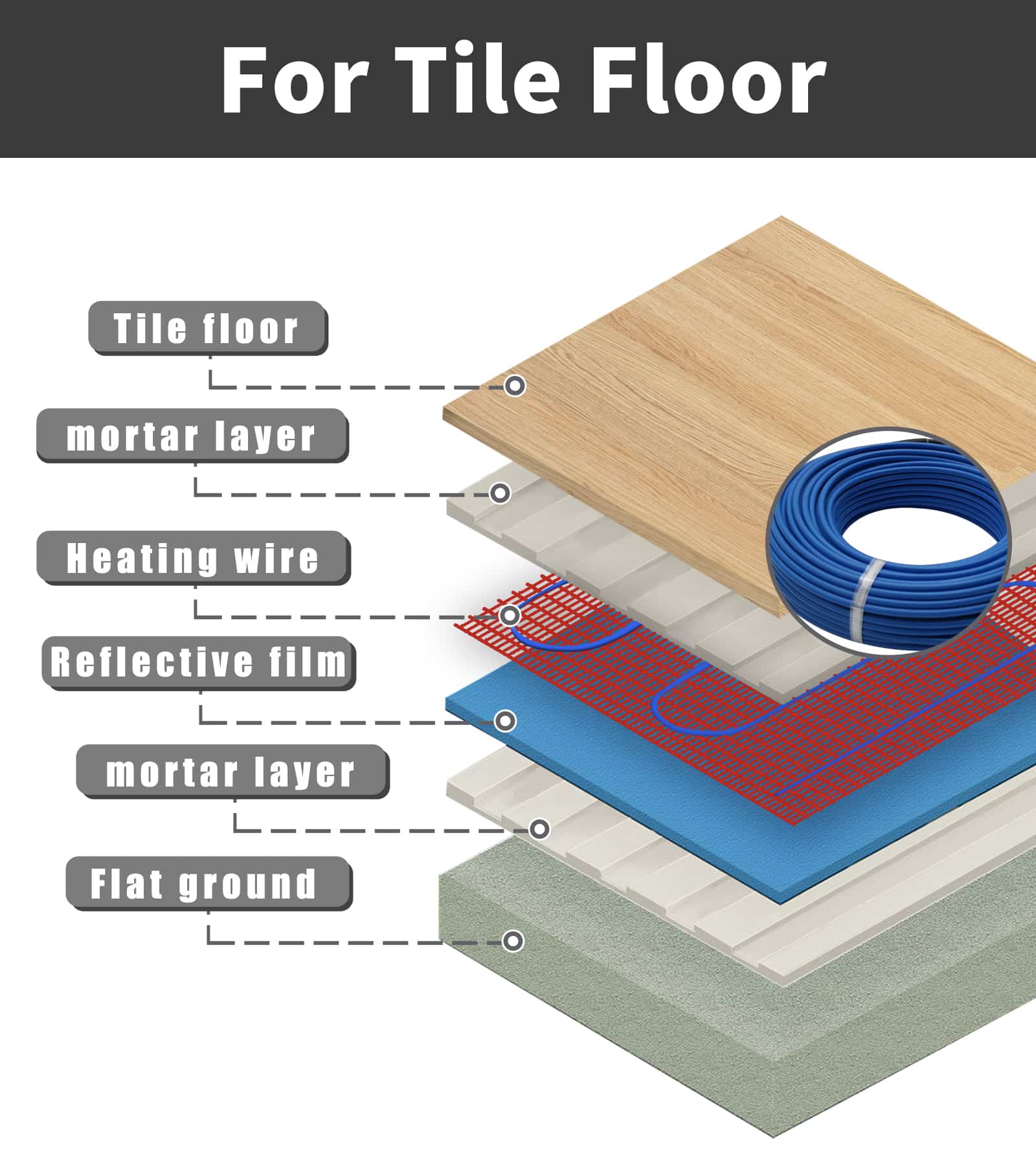

- Site preparation: Clean the installation surface to ensure there are no sharp foreign objects (such as nails, gravel), and avoid scratching the surface of the heating mat; If the installation surface is uneven (such as the outer wall of industrial equipment), it is necessary to use high-temperature resistant tape to level it, ensuring that the heating seat is tightly attached (reducing heat loss).

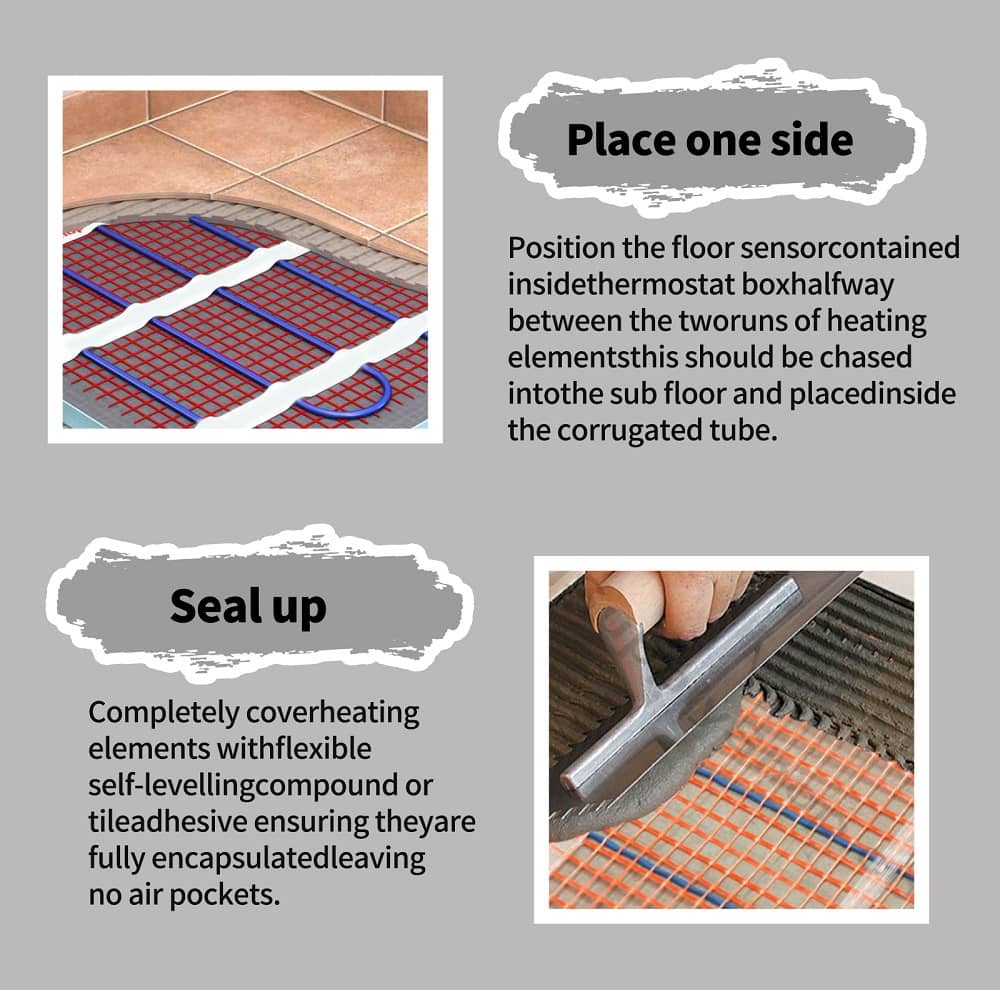

- Wiring and fixing: Connect the power supply according to the instructions of the heating seat (matching the rated voltage, 220V for household use, and 380V for industrial equipment), and seal the wiring with waterproof terminals (universal for all environments to prevent short circuits); Use heat-resistant tape or buckles to secure the heating mat and avoid displacement (especially in outdoor and industrial settings, to prevent it from falling off due to wind or equipment vibration).

- Testing and debugging: Before powering on, use a multimeter to check the resistance of the heating seat (consistent with the instructions to rule out open circuits); After powering on, run at low power for 30 minutes to check for local overheating (detected with an infrared thermometer, temperature deviation should be ≤ 5 ℃), and at the same time test whether the temperature controller (if any) starts and stops normally.

2. Special installation requirements for different environments

Family environment (bathroom/bedroom):

- The installation of the bathroom should be away from the shower area (at least 1.5 meters), the power socket should be equipped with a "splash box", and the edge of the heating seat should be 2cm above the ground (to prevent water from overflowing).

- The heating mat of the bedroom mattress cannot be folded for use (to avoid the breakage of heating wires), and heavy objects (such as heavy mattresses and suitcases) should not be pressed to prevent local temperature from being too high.

Industrial environment (equipment/pipelines):

- When installing the outer wall of the equipment, the heating mat should avoid the equipment interface and valves (to prevent scratching during operation), and an insulation layer (such as rock wool or glass wool) should be wrapped around the outside of the heating mat to reduce heat loss to the air and save more than 30% energy.

- When installing pipeline heat tracing, the heating mat needs to be spiral wound (with a spacing of 5-10cm, adjusted according to the diameter of the pipeline), and cannot overlap (overlapping areas will double the temperature and cause burning).

Agricultural environment (soil/nursery box):

- When installing underground in soil, a layer of PE waterproof film should be laid first (followed by a heating mat, and finally covered with soil). The waterproof film should extend 30cm beyond the edge of the heating mat (to prevent soil moisture from seeping in), and the soil cover thickness should not exceed 10cm (too thick will reduce thermal conductivity efficiency).

- When installing the seedling box, the heating mat should be placed in the middle position at the bottom of the box, with a layer of insulation board on top (to avoid direct heat damage to the seedling roots), and then the seedling tray should be placed.

Outdoor environment (tent/trail):

- When installing inside the tent, the heating mat should be placed above the moisture-proof mat (to avoid moisture erosion on the ground), and should not be close to flammable materials in the tent (such as canvas, down sleeping bags, at least 30cm away).

- When assisting with snow melting on outdoor trails, the heating mat should be buried 5-8cm below the trail bricks, leveled with fine sand above (and then paved with step bricks), and linked with rain and snow sensors (only activated during snowfall to avoid energy consumption).

Core avoidance points for selection and installation

- Do not blindly pursue high power: excessive power in household scenarios can easily lead to overheating and increased power consumption; Excessive power in agricultural scenarios can damage crop roots, and the power should be calculated based on the "required temperature of the environment" (such as maintaining a soil temperature of 15 ℃, selecting 80W/㎡ is sufficient).

- Do not ignore the protection level: Heating mats with IPX4 or below in the bathroom are prone to short circuits due to splashing water; Industrial outdoor use with IPX5 or below may damage internal components due to rainwater intrusion, and the correct level must be selected according to the environmental humidity.

- Do not omit testing after installation: do not check the resistance before powering on, there may be a risk of open circuit; Not testing the local temperature may lead to local overheating due to uneven adhesion, especially in industrial and outdoor scenarios, where later maintenance is difficult. Early testing can avoid more than 80% of faults.