In addition to launching more competitive new energy models, automakers are also intensively laying out charging networks. In the past two years, 800V high-voltage platforms and 4C charging technologies have been launched one after another, and the era of comprehensive fast charging is approaching. Tesla, Xiaopeng, Ideal, Zeekr, Huawei and other companies are accelerating the construction of supercharging stations and supercharging piles across the country, providing higher charging power and energy replenishment efficiency to bring an evolved charging experience to end users and eliminate mileage anxiety.

On the policy side, the country's strong support for new energy vehicle charging facilities is driving it to become an emerging hot market. As early as 2020, new energy charging piles have been included in one of the seven key areas of "new infrastructure". After years of development, it has been quite effective. According to statistics from the China Charging Alliance, in 2023, the increase in charging infrastructure will be 3.386 million units, and the increase ratio of piles to vehicles will be 1:2.8, which means that the construction speed of charging piles can basically meet the rapid development of new energy vehicles.

When the focus is on the charging pile industry chain, downstream companies have an increasingly strong demand for high-power supercharging, DC fast charging, liquid cooling, etc. This demand is transmitted to upstream charging equipment component suppliers, including charging guns, charging cables, power modules, controllers and other components must be upgraded accordingly, and meet safety requirements such as high temperature resistance and high voltage resistance to support the implementation of higher-specification charging piles.

In the design of charging piles, the choice of materials is crucial. Especially for indicators such as thermal conductivity, sealing, insulation, and flame retardancy, breakthroughs in materials are needed, including silicone materials. Silicone can be used as thermal conductive adhesive, sealant, adhesive, etc., and is widely used in core components such as thermal management, charging protection, and power modules of charging piles, playing a key role in charging pile components.

What challenges does the popularization of supercharging technology bring to charging facilities?

If new energy vehicles want to get a charging experience close to that of fuel vehicles, they must improve their charging efficiency in an all-round way. This is why car companies are striving to bring 4C or even 5C supercharging technology to consumers while promoting the 800V high-voltage platform.

In August 2023, CATL launched the world's first lithium iron phosphate 4C supercharging battery-Shenxing Supercharging Battery, claiming to achieve 10 minutes of charging and a range of 400 kilometers. After that, 4C fast charging has entered the field of vision of consumers more and more frequently.

How is 4C supercharging defined? Simply put, XC refers to the charging rate, that is, the ratio of the maximum charging current that the battery can accept during charging to the rated capacity of the battery, represented by C, which is usually used to describe the speed of charging. Specifically, if the vehicle is equipped with a 100kWh battery pack, the charging power can reach about 200kW at a rate of about 2C; at a rate of about 4C, the charging power can reach about 400kW; at a rate of 6C, the charging power can reach about 600kW. In short, the higher the charging rate, the faster the charging speed.

If you want to truly popularize supercharging, in addition to power batteries and high-voltage platforms, you must also adapt to high-power DC charging piles. The power output capacity of the charging pile and the stability of the power supply will affect the charging rate. High-power charging piles and stable power supplies can provide higher charging rates.

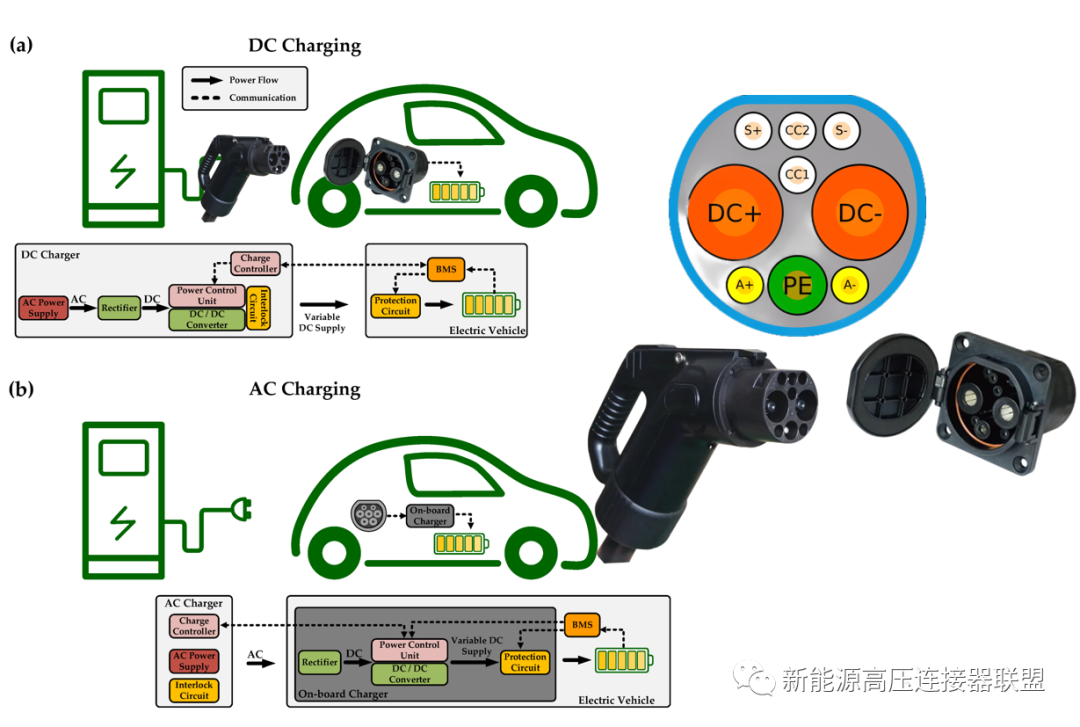

The charging pile is mainly composed of charging gun, charging cable, shell, control module, thermal management module, charging protection module and other components. From AC slow charging to DC fast charging, and then to super fast charging, which may gradually become popular in the future, all components need to be upgraded iteratively to adapt to the change of charging power.

In fact, before the super charging technology, in the process of the development of charging piles from AC slow charging to DC fast charging, problems such as high cost, grid burden, compatibility, battery life, and difficult installation have been roughly solved.

On the basis of DC fast charging technology, super fast charging provides a higher charging rate, so the charging pile needs to bear higher power, larger current, and higher heat generation. At the same time, it is also necessary to solve the problem of excessive size and weight of the charging pile and stricter cable flexibility requirements.

For the charging gun, in order to achieve fast charging, the super charging gun needs to be able to transmit large current. This requires the charging gun to have good conductivity and heat dissipation design to ensure safe and efficient current transmission.

Supercharging technology also needs to be equipped with a complete safety protection mechanism, including overcurrent protection, overvoltage protection, short circuit protection, etc. Charging piles and charging guns should have monitoring and protection functions to prevent malfunctions and dangers during charging.

Not only that, since high-power charging will generate a lot of heat, charging piles and charging guns need to be equipped with an effective cooling system to prevent overheating, including fans, heat sinks, water cooling and other heat dissipation methods.

What are the requirements for materials for the upgrade of charging facilities?

With the increase in charging power, charging piles not only need to design more advanced structures to meet the thermal conductivity under high power, but also, on the material side, it is imperative to use materials with strong insulation, high temperature resistance and high thermal conductivity.

Taking the thermal management system of charging piles as an example, unlike traditional air cooling, supercharging requires more use of liquid cooling to solve efficiency and heat dissipation problems. At present, the most commonly used liquid cooling methods on the market are water-based cooling and oil-based cooling. Water cooling has better heat dissipation performance, lower cost, and is more environmentally friendly; oil cooling has good electrical insulation, lower evaporation rate and chemical stability.

In the past few years, oil-cooled cables have been used in super charging guns, gaining a first-mover advantage. At present, some manufacturers have developed oil-cooled super charging piles and charging guns, but as the operating time goes by, the cost disadvantage of oil cooling becomes more and more prominent. Now more manufacturers are beginning to study and test water-cooled cables and water-cooled super charging guns.

The working principle of water-cooled cables and water-cooled super charging guns is that the water-cooling tube is designed outside the multi-strand charging wire, and water flows in the middle of the tube. Relying on the thermal conductivity of the tube itself, the heat generated by the multi-strand charging cable is transferred to the coolant in the middle of the tube. These coolants exchange heat with the outside world through electronic pumps to achieve temperature control of cables and super charging guns.

Based on this principle, many manufacturers used ordinary nylon tubes as the water-cooling tubes in the middle of water-cooled cables. Due to the use of PA material, the thermal conductivity is only 0.2W/m·K. When the current exceeds 400A, the temperature rise accelerates sharply. At this time, due to the insufficient thermal conductivity of the water-cooling tube, the heat cannot be transferred out in time. After calculation, it was found that based on the common structure of the current cables, if the goal of high current fast charging is to be achieved, the thermal conductivity of the cold water pipe must be greatly improved, at least 1.5W/m·K or more. Therefore, the upstream and downstream of the industry chain pay more and more attention to the innovative application of high thermal conductivity materials, and thermal conductive silicone tubes have become one of the key components of thermal management of super charging piles.

In addition to the temperature control of the charging cable, how to reduce the temperature rise of the charging gun head during the charging process is also a pain point in the current charging pile design. At present, it is difficult to solve the heat dissipation problem by air cooling. By using innovative thermal conductive potting glue, the heat of the gun head connector can be efficiently transferred out to ensure that the charging efficiency will not decrease due to the temperature increase, and at the same time, the user experience during operation can be further improved.

On the other hand, when the voltage platform of new energy vehicles in the future generally reaches 800V, the charging current reaches 600A, and the charging power reaches more than 400kW, any problems in the charging process may cause extremely serious consequences. Therefore, the sealing and anti-leakage properties of structural materials will be unprecedentedly valued.

Under the new trend, how to innovate on the material side?

When it comes to upstream material suppliers in the charging pile industry chain, Dow is the first to bring many innovative designs and cutting-edge ideas to the industry. Dow can not only provide a rich selection of materials, but also customize exclusive solutions for higher-power DC fast charging infrastructure (including charging stations, charging guns (connectors), cables and charging cabinets) to meet more stringent market needs.

In the field of charging facilities, Dow focuses on three major directions. First, in terms of thermal management materials, Dow provides a wide range of adhesive products including caulking agents, adhesives, non-curing thermal interface materials, immersion coolants, gels and potting glues to solve the heat dissipation pain points in charging facilities; in terms of protection and assembly materials, Dow provides adhesives, sealants and conformal coatings to provide all-round protection for charging components; in addition, Dow can also provide elastomers, solid thermal conductive silicone rubber and liquid silicone rubber to support insulation, thermal conductivity and other needs.

For example, capturing the thermal conductivity requirements of the charging cable mentioned above, Dow has developed a new thermal conductive silicone rubber - SILASTIC™ HTE5015-90U silicone rubber, which solves the key technical difficulties in the water-cooled super charging gun solution - the cooling water pipe must have both high thermal conductivity and high strength and high toughness materials. The most significant advantage of this product is that it has a higher thermal conductivity, with a thermal conductivity of up to 1.5W/m·K, which can cool the cable of the super charging gun with a current of 600A and provide thermal protection. At the same time, good physical properties and resistance to harsh environments allow it to be used to extrude thermally conductive silicone tubes. High hardness and high strength enable direct twisting with cables. In addition, better flexibility, durability, high and low temperature resistance, coolant resistance, insulation and other indicators provide long-term protection for super charging guns.

In response to the heat dissipation and sealing needs of charging gun heads, Dow has developed a series of products. Dow's DOWSIL™ TC-6040 thermal conductive potting glue has a thermal conductivity of 4.0W/m·K, which can quickly cool down overheated charging guns, which will not be hot, and ensure the normal operation of the modules inside the system, especially the most important inverter module. Long-term reliability; for the sealing requirements of liquid-cooled charging piles, the sealing rings and wiring harness sealing rings made of Dow's silicone elastomer materials have achieved good waterproof effects.

Conclusion

After years of vigorous development in the new energy vehicle industry, the pain points of end users have gradually transitioned from cruising range to efficient energy replenishment experience, and the promotion of high-power and high-efficiency charging facilities is imminent. In this process, upstream and downstream companies in the industrial chain need to work together to cope with the various challenges faced by the fast charging trend, from batteries to charging facilities, from materials to applications. We hope that the leading companies in the upstream and downstream of the industrial chain can bring more efficient and easy-to-use solutions to the fast charging development of new energy vehicles.